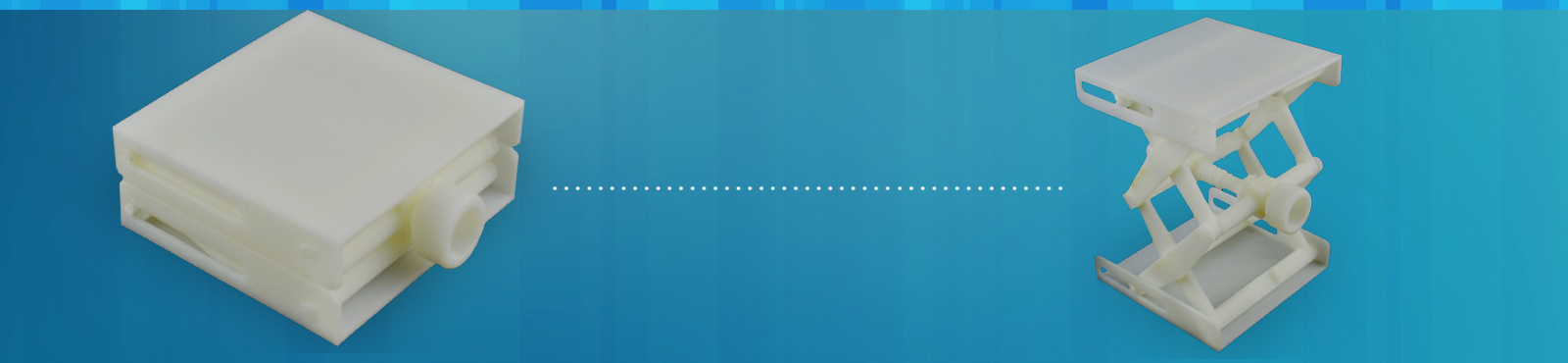

The Proces of making prototypes

apid prototyping is a process of creating prototypes that will be a protoplasts of a finished product. The most popular methods to make prototypes are additive methods, where 3d printers are used. This way of production is called rapid prototyping (because in a short time we can make any prototype part from the CAD design).

One of the most popular technology of additvie manufacturing methods is FDM or FFF. It is base on heat and thermoforming material, where the hot-end melts stiff plastic into the melt form and applies layer upon layer. The range of temperature is determinated by the material. Normally, it is between 190-260°C.

Perfest technology to make :

- enclosures,

- prototypes of the functional parts,

- construction model or even finished parts

The huge advantage of those methids is a range of the materials available to use, which results in a prototype that strongly imitates the desired product.

Also popular, the DLP method, uses the projector light to harden layer upon layer, the photosensitive resin. It allows to make high resolution models, with the precision of 20 um. Additionally, it is possible to use wax-like resins, used in lost-wax casting. It’s mostly used in the jewelry industry to create intricate designs, impossible to achieve wtih traditional methods.

![]()